Spindelservice vom Marktführer – in Premiumqualität für höchste Lebensdauer

Spindelausfälle nachhaltig um 50 % reduzieren und Produktionsverzögerungen fast vollständig vermeiden

Wirtschaftlich

20–30 % Kostenersparnis gegenüber dem Kauf einer Neu- oder Tauschspindel bei neuwertiger Qualität der reparierten Spindel.

Schnell

Erhalten Sie Ihre Spindel innerhalb von 6 bis 8 Tagen so gut wie neu und in erstklassiger Qualität zurück.

Langlebig

Unsere reparierten Spindeln halten laut Erfahrungen hunderter Kunden im Schnitt doppelt so lange wie zuvor.

Neuwertig

Die Qualität unserer Spindelreparaturen ist mit der Qualität und Funktionalität einer Neuspindel gleichzusetzen.

Über 16.000 reparierte Motor- und Riemenspindeln namhafter Hersteller

Mehr als 3000 zufriedene Kunden in über 25 Ländern weltweit

Mit über 2800 m² Firmenfläche und mehr als 16.000 reparierten Motospindeln ist die KERN GmbH eines der modernsten Spindel-Reparaturzentren in Europa. Wir bieten Ihnen Spindelreparaturen in Premiumqualität für sämtliche Hersteller und Fabrikate – mit mehr als 35 Jahren praktischer Erfahrung. Gleichzeitig organisieren wir bei Bedarf auch den Ein- und Ausbau Ihrer Spindel. Testen Sie unseren Expressservice: Kessler, DMG, SW, Weiss, Heller und viele weitere Spindeln innerhalb von 6 bis 8 Werktagen.

DIese Kunden halten ihre Produktion durch unsere Spindelreparaturen nachhaltig am Laufen:

Warum sich hunderte Industrieunternehmen weltweit für Kern GmbH entscheiden

Über 35 Jahre Erfahrung

Als weltweiter Vorreiter für nachhaltige und langlebige Spindelreparaturen gehören für uns auch komplexere Reparaturen zur Routine. Durch unsere Erfahrung denken wir vorausschauend und sorgen dafür, dass Spindeln für die jeweilige Anwendung ideal optimiert sind und es zu deutlich weniger Ausfällen kommt – die Folge ist eine hohe Maschinenverfügbarkeit und geringere Kosten.

Hohe Effektivität

Unsere reparierten & optimierten Spindeln zeichnen sich dadurch aus, dass sie oft mehr als die doppelte Laufzeit erreichen. Dadurch reduzieren Sie Spindelausfälle nachhaltig um bis zu 50 %.

Schnelle Spindelreparatur

Oftmals muss es schnell gehen. Durch exzellente Prozesse können wir Spindeln innerhalb von 6 bis 8 Werktagen vollständig instand setzen.

TOP PREIS-LEISTUNGS-VERHÄLTNIS

Laut hunderten Kunden erreichen unsere reparierten Spindeln eine außerordentlich lange Laufzeit bei gleichbleibender Präzision. Daher versprechen unsere fairen Preise besonders auf langfristige Sicht ein hervorragendes Preis-Leistungs-Verhältnis.

Ihre KERN Vorteile auf einen Blick

Wir reparieren wälzgelagerte Spindeln von fast allen Herstellern

Kessler

Mazak

Matsuura

Makino

Fischer

Weiss

Renaud

Omlat

Deuschle

Blohm

Reckerth

Fiege

Fortuna

SLF

SPL

IMT

Voumard

Blombach

StepTec

GMN

Mikron

Grob

Gamfior

Hessap

UVA

IBAG

HüllerHille

Chiron

DMG

Unior

HS-Tec

Cocom

Moore

UKF

Hurco

Hermle

ABA

Bridgeport

Jukomet

Techno u.v.m.

Fragen Sie jetzt eine Spindelreparatur für Ihre Spindel herstellerunabhängig an.

Wenn eine Spindel spontan ausfällt, wiegen die Konsequenzen oftmals schwer.

Und vermutlich stehen auch Sie vor einer dieser 4 Herausforderungen:

Sinkender Umsatz

Stress

Verzögerungen führen zu unzufriedenen Kunden, die sich beschweren und die man so schnell wie möglich beliefern muss.

Teurer Ersatz

Eine neue Spindel direkt vom Hersteller ist meistens nicht direkt verfügbar und deutlich teurer als die Spindelreparatur.

Verminderte Qualität

An Tauschspindeln wird in der Regel nur das Nötigste repariert, damit sie schnell wieder im Einsatz sind – was ihre Lebensdauer deutlich verringert.

Welche Ergebnisse Sie erwarten können

Expressreparatur

Innerhalb von 6–8 Werktagen erhalten Sie von uns Ihre Spindel so gut wie neu zurück. Wenn es sehr schnell gehen muss, legen wir auch Extraschichten am Samstag ein. Übrigens: Wir verlangen bei Expressreparaturen keine extra Kosten.

Wartung

In regelmäßigen Abständen schauen wir uns präventiv Ihre Spindeln an, um Ausfällen vorzubeugen. So können Sie Produktionsstopps und größere Reparaturen verhindern.

Nachhaltigkeit

Uns ist es wichtig, dass Ihre Spindel lange hält und Ihnen zu einer hohen Produktivität und Maschinenverfügbarkeit verhilft. Daher schauen wir uns jedes Element einzeln an, optimieren es oder tauschen es aus, bis alle Teile einwandfrei funktionieren.

Full-Service

Von der Abholung und bei Bedarf auch dem Ausbau Ihrer Spindel über die ganzheitliche Reparatur bis zum Rücktransport und Einbau – wir kümmern uns gerne um die gesamte Abwicklung für Sie.

Mit diesen Leistungen unterstützen wir Sie

Wir stellen unseren Kunden eine breite Servicepalette zur Verfügung. Dabei arbeiten wir mit allen Spindeltypen sowie komplett herstellerunabhängig und können Ihnen eine ehrliche & faire Beratung durch unser Team versichern.

Spindelservice

Wir halten Ihre Spindeln instand, kümmern uns um die Wartung und beraten Sie vollumfänglich zu möglichen Verbesserungsmaßnahmen – nicht nur an der Spindel selbst, sondern z. B. auch an der Maschine.

Spindelreparatur

Wir reparieren Ihre Spindel nicht einfach nur – wir nehmen nachhaltige Optimierung vor, sodass sie Ihnen in den nächsten Jahren keine Schwierigkeiten mehr bereitet.

Vollumfänglicher Spindelservice:

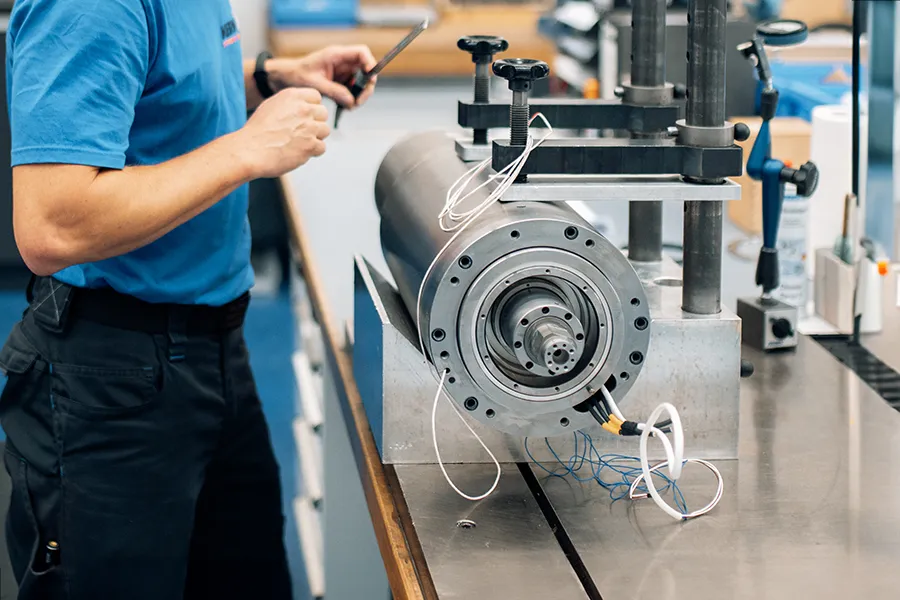

So reparieren & warten wir Ihre Spindel

Wir können mit Spindeln aller Fabrikate und komplett herstellerunabhängig arbeiten. Die Instandsetzung folgt dabei einem erprobten 6-Schritte-Prinzip, das den kompletten Bereich von der Abholung bis zur Rückgabe abdeckt.

Fallstudien: Unsere Erfolgsgeschichten

REPARIERTE, NEUWERTIGE MOTORSPINDEL FÜR LIEBHERR

30 % gespart gegenüber einer neuen Spindel

30 % gespart gegenüber einer neuen Spindel

Aufarbeitung aller Motorspindeln

Aufarbeitung aller Motorspindeln

Bosch arbeitete mit Motorspindeln, die häufig kaputt gingen und zu Produktionsverzögerungen führten. Um das in Zukunft so gut wie möglich verhindern zu können, entschied sich das Unternehmen, unser Full-Service-Paket in Anspruch zu nehmen.

ANSTATT KAUF EINER NEU- ODER TAUSCHSPINDEL FÜR ZF

Kostenersparnis von 30 % durch Reparatur

Kostenersparnis von 30 % durch Reparatur

Full-Service mit Ein- und Ausbau

Das sagen unsere Kunden

Wir haben Ihr Unternehmen um eine Notfallreparatur einer Weisser Elektrospindel gebeten. (…). Tatsächlich erlaubte uns die Reparatur, unsere Anlagen am Samstagmorgen um 10:30 Uhr neu zu starten. Wir konnten dadurch am Wochenende weiter produzieren und ein Maschinenstillstand wurde verhindert. (…) Insbesondere haben wir die Verfügbarkeit, Reaktionsfähigkeit und Professionalität geschätzt, die Sie bewiesen haben. Deshalb möchten wir uns bei Ihnen bedanken und freuen uns auf die Zusammenarbeit mit Ihnen.

Eric Schwarz Responsable Fournitures Prestations Industrielles, PSA Group

Sehr geehrter Herr Steeb, wir freuen uns, Ihnen mitteilen zu können, dass die Spindel, die Sie für uns repariert haben (auf unserer Fehlamm P95 Maschine), problemlos installiert wurde und einwandfrei funktioniert. Unserer Meinung nach wurde die Reparatur in sehr hoher Qualität und im vereinbarten Zeitrahmen durchgeführt. Vielen Dank für Ihre gute Arbeit.

Robert Gačnikar, GALERO

Gratulation und 1000 Dank für diese sagenhafte Performance an alle Mitwirkenden. Viele Grüße aus Brandenburg.

Klaus Jacob, Teamleiter Werkstechnik Schlote Group

Jetzt unseren exklusiven Spindelreport 2023 sichern!

In unserem exklusiven Fachreport finden Sie interessante Fakten:

Typische Spindelprobleme und wie man sie behebt

Die 3 Faktoren für die Effizienz einer Spindel

Beispiele unserer Kunden mit konkreten Zahlen, Daten & Fakten

Kostenlosen Report anfordern

Einfach Formular ausfüllen, um den kostenlosen PDF-Download direkt per Mail zu erhalten.

Ihr Weg zu uns

Beratung

Kontaktieren Sie gerne uns via Telefon, E-Mail oder über unser Kontaktformular – bei einem konkreten Spindelausfall oder falls Sie allgemein Interesse an einer Zusammenarbeit mit uns haben.

Abholung

Gerne holen wir Ihre Spindel ab und bauen diese bei Bedarf auch vor Ort aus. Selbstverständlich können Sie die Spindel auch selbst zu uns bringen.

Prognose

Anhand Ihrer Schilderung erstellen wir Ihnen eine ungefähre erste Prognose. Im Anschluss schauen wir uns die Spindel detailliert an und erstellen einen Kostenvoranschlag.

Umsetzung

Wir demontieren Ihre Spindel zügig, um herauszufinden, an welchen Stellen die Probleme auftreten. Sie erhalten eine Übersicht über die notwendigen Maßnahmen und Kosten der Reparatur.

reparierte Spindeln pro Jahr

zufrieden bediente Kunden

Jahre Erfahrung

Standorte weltweit

Wir reparieren Ihre Spindel präzise und halten sie zuverlässig instand.

Unsere Standorte

Wir haben mittlerweile 4 Niederlassungen weltweit aufgebaut, von wo aus wir unsere internationalen Kunden betreuen. Unser Lager in Burladingen gilt mit seinem hochwertigen Equipment und seinen 2.800 m² Größe als die modernste Spindelreparatur-Einrichtung der Welt.

Aber auch all unsere anderen Standorte im Ausland sind sehr fortschrittlich und verfügen über die neuesten und besten Arbeitsgeräte. So wird beispielsweise überall die Luft 7-mal pro Stunde gereinigt, um eine staubfreie Atmosphäre sicherzustellen.

Unsere Halle in Deutschland

72393 Burladingen

Unser Sitz in der Volksrepublik China

215321 Kunshan

Unser Spindelservice in Südkorea

Giheung-gu, Yongin-si

Unsere Niederlassung in Mexiko

FAQ – Häufig gestellte Fragen

„Wie lange dauert die Instandsetzung?“

Tendenziell können wir Expressreparaturen innerhalb von 6–8 Tagen durchführen. Wenn es wirklich schnell gehen muss und wir sehen, dass es für Sie dringlich ist, können wir die Reparatur in Einzelfällen auch in 4 Tagen erledigen.

„Haben eure optimierten Spindeln wirklich so eine lange Standzeit?“

Wenn wir Ihre Spindel demontieren, schauen wir uns jedes Einzelteil an. Wir reinigen alle Komponenten und tauschen diejenigen aus, die man nicht mehr ausbessern kann. Dadurch erhalten Sie am Ende eine Spindel, die so gut wie neu ist und tendenziell sogar länger hält als eine neue vom Hersteller. Wir machen Ihnen als zuverlässiger Partner auch gerne das Angebot zur regelmäßigen Wartung Ihrer Spindel.

„Warum sollte ich mich gegen eine Neu- oder Tauschspindel entscheiden?“

Bei Tauschspindeln wird nur das repariert, was dafür sorgt, dass die Spindel wieder einsatzfähig ist. Das ist nicht sehr teuer und geht schnell. ABER die Wahrscheinlichkeit, dass nach kurzer Zeit wieder Schäden auftreten, ist sehr hoch. Denn wenn die Spindel im Ganzen nicht instand gehalten wird, verschleißen die Einzelteile nach und nach, was zu ständigen Ausfällen führt. Das Problem hat man bei einer neuen Spindel nicht. Jedoch sind diese sehr teuer und meistens auch nicht sofort verfügbar. Eine von uns optimierte Spindel bietet daher den perfekten Zwischenweg.

Wollen Sie Ihre Spindel reparieren oder warten lassen?

Dann nehmen Sie jetzt Kontakt mit uns auf und vereinbaren Sie eine unverbindliche Beratung. Hier können Sie uns Ihre Situation schildern und wir erklären Ihnen genau, wie wir bei einer Spindelreparatur vorgehen.